What if you could increase the energy efficiency and lifetime of all drives at your plant while at the same time increasing the capacity of your electrical distribution? Depending on the levels of harmonic distortion on site, that may be a possibility.

Harmonic distortion refers to the distorting of the 50 Hz voltage and current AC sine waveform. It’s become a significant and widespread power quality problem with the exponential growth of the use of nonlinear loads (modern electrical equipment which does not draw current as a sine wave). These loads can cause a distorted voltage waveform across the site which has varying impacts across all electrical equipment and distribution infrastructure on site.

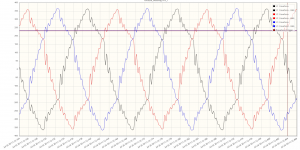

A 3-phase voltage waveform taken at the main switchboard on a site with a number of variable speed drives (VSDs). The voltage waveform is significantly distorted from a sine wave shape.

Some of the adverse effects of high harmonic distortion are:

- Heating losses in loads and infrastructure (e.g. motors, cables, transformers…)

- Higher order harmonics burning out capacitors, causing failure of electronic equipment

- Misfiring of switching devices and timing circuits that rely on waveform “zero crossings”

- Reduced lifetime of motors and other equipment

- Plant/equipment trips due to higher RMS currents.

- Not meeting connection requirements of the Local Network Service Provider

All of these have the combined effect of reduced energy efficiency, reduced reliability and capacity of the power distribution network and reduced lifetime of equipment.

Thankfully, technology to mitigate harmonic distortion has accelerated alongside the proliferation of the problem. Both passive and active electrical devices can be added to a network to filter out harmonic distortion.

Passive filtering uses fixed inductance and capacitance elements to filter out harmonics, however needs careful design to avoid adverse interaction with the power system and design can be difficult where system characteristics are changing. Active harmonic filters inject current to cancel out harmonic frequencies in a dynamic and rapidly responding way, achieving the best-possible result.

Provecta offers turn-key solutions for harmonic distortion mitigation including initial monitoring and analysis, through to design, supply and commissioning of harmonic filters.